Equipment: 3 bauxite dryers

Dimensions: Length 48 m x diam. 4.8 m

Sector: Bauxite ( rep. of Guinea)

Context: Total refurbishment of three units.

Services: Audit, diagnostic & recommendations

SERCEM INDUSTRIE is well known in the field of heavy mechanics for 50 years in the suburb of Lyons in France .

Our customers are renowned international operators such as Lafarge- Holcim , Heidelberg, Alcoa , Rusal etc ..

They are all world leaders in the field of mining , cement & mineral chemistry .

Our know how is the mechanical improvement of production equipments such as rotary kilns , rotary dryers , mills, crushers etc…in France and abroad .

In this case, one of our customers based in republic of Guinea in the field of bauxite ore, asked us to renovate 3 rotary dryers.

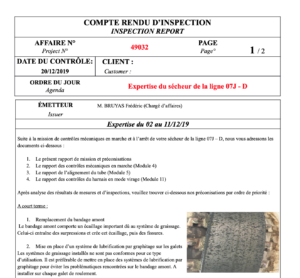

We propose to our client a preventive maintenance project. First of all, we have to carry out a “zero point”.

We will therefore start with a complete expertise of each bauxite dryers

Module 1 . Inspection of shell deformation

- Laser acquisition of the shell profile: 1 section every meter along the entire length of the dryer.- 12 to 16 points per section

- Processing and providing a report for each section

- Delivery of a global report (3D curve graphically synthesizing all the sections)

Module 5 . Alignment checks : (Equipment at standstill, no turn)

The position of the shell centers at the supports

Module 4 . Mechanical Inspections of the bauxite dryers :

The position and parallelism of the axes of the rolling elements, which requires measuring :

- Drum slope,

- Chassis and inter-chassis slopes,

- Rollers slopes,

- Wheel spacing and turning angle of the rollers

- Ø and shapes rollers / tires

- Thrust position,

- Up and down movement and respective positions of the rolling elements

Module 2 . Cartography of shell thickness:

On 2 generators (from the inside), 1 point every 500 mm

Module 5 . Girth gear & pinion static inspection .

Following the audits carried out and the data collected, we provided the client with a precise diagnosis including recommendations for works to be carried out in the short and medium term.

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.